In a serious and responsible attitude, we will provide every product and attentive service for every customer. Pay attention to details, keep improving, and constantly upgrade, so that our equipment accuracy, speed and intelligence continue to improve, the machine operation is simple, convenient and easy to use. Consultation hotline (7 * 24 hours)188-2007-2813

Sulfuric acid filling and screwing cover production line

Sulfuric acid production line features:

1. Automatic production line flow: manual bottle conveyor belt – automatic filling – automatic capping – automatic capping – Manual bottle closure

2. Filling is made of special PVC material with internal acid and alkali resistance and corrosion resistance. It is controlled by PIC and touch screen. The equipment is easy to operate and durable.The lid is made of automatic cover and spin cap.

3. technical parameters:

(1) bottle width: customized according to customer’s products.

(2) bottle height: can be customized according to customer’s products.

(3) filling capacity: 500-1500ml (other specifications can be customized as required).

(4) number of filling heads: customized according to production requirements.

(5) filling accuracy: + 1% (equal capacity filling)

(6) production speed: customized according to production requirements.

(7) air pressure: 0.6-0.8Mpa

(8) air consumption: 200 litres / min.

(9) power supply: 380V/50HZ, three-phase five wire system.

(10) whole line power: 23KW

This product line is also suitable for packaging of acid and alkaline products such as detergents, toilet cleaners, etc.

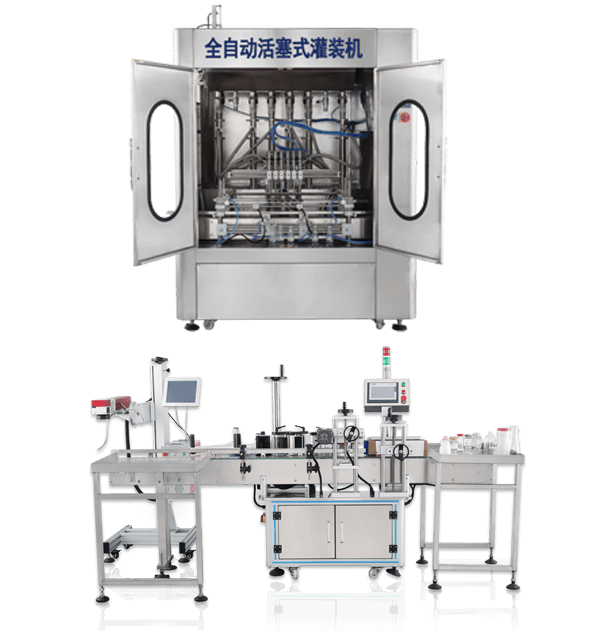

Filling machine

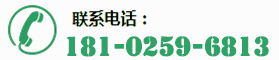

Filling machine Labeling machine

Labeling machine Screw cap machine

Screw cap machine Casing shrink..

Casing shrink.. Bottle washing..

Bottle washing.. Automatic medicin.

Automatic medicin. Automatic filling ..

Automatic filling ..  Automatic filling ..

Automatic filling ..