In a serious and responsible attitude, we will provide every product and attentive service for every customer. Pay attention to details, keep improving, and constantly upgrade, so that our equipment accuracy, speed and intelligence continue to improve, the machine operation is simple, convenient and easy to use. Consultation hotline (7 * 24 hours)188-2007-2813

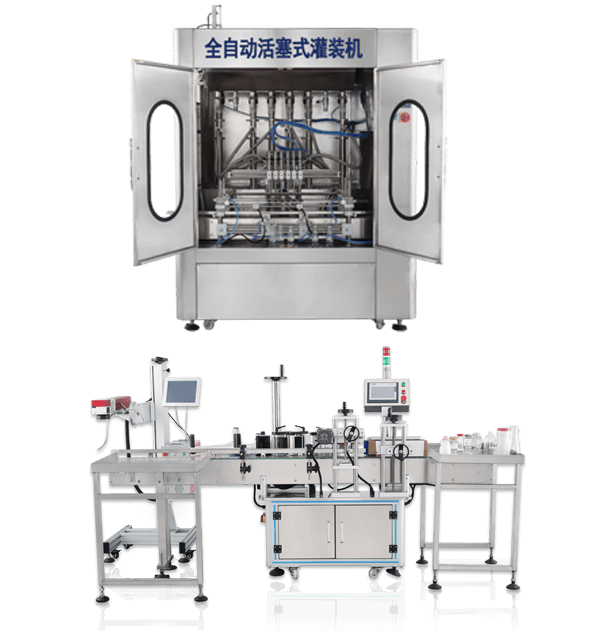

Hot filling production line of wax

Technical parameters:

(1) number of filling heads: 681012 (according to customer’s output).

(2) filling capacity: 50-5000 ml (customized according to customer requirements)

(3) filling form: servo piston quantitative filling.

(4) filling speed: 1000-2500 bottles / hour (as required by customers).

(5) filling accuracy:%%p1% (40-200 ml)%%p2% (20-40 ml)

(6) material: filling frame adopts 304 stainless steel.

(7) program control: import PLC with touch-screen man-machine interface.

(8) contact parts of pistons and grooves and filling mouths: 316L stainless steel and heat resistant engineering plastics.

(9) sealing ring material: PTFE

(10) air pressure: 0.5-0.8MPa

(11) conveyor belt: 82 mm POM chain strip.

(12) driving motor: 550W variable frequency speed regulating motor

(13) total height: 2.3 M.

(14) material tank heating: room temperature -80 degrees Celsius adjustable, 6KW stainless steel heating tube heating

(15) material tank capacity: 100 liters.

(16) pipe insulation: up to 80 degrees Celsius.

(17) material trough mixing: 370W motor, speed transducer and speed regulation.

(18) total power: 10KW/380V three-phase five wire power supply

5 channel refrigerator

Technical parameters:

1. appearance size: 3500mm (L) X940mm (W) X1400mm (H)

2. compressor: 5 (US)

3. power supply: 3 phase 380V/50HZ

4. machine power: 4KW

5. refrigerator door: 4 door

Size 2800mm (L) X940mm (W) X1400mm (H)

6. Conveyor belt size: 3500 mm *82.6 mm (POM) plastic steel chain conveyor belt from the ground height: 740 mm – 760 mm adjustable

7. fuselage material: (SUS304) fuselage design

8. conveyor belt motor: Taizhou purple 370W motor

9. temperature control: -10 degrees Celsius – room temperature adjustable

10. the conveyor belt for refrigerators is multi track type.

Chuck type outer cap Capping Machine

Technical parameters:

Suitable for bottle body diameter: Chuck should be replaced in different specifications.

Applicable cap diameter: 50-80 mm adjustable.

Lower cover way: cover ladder belt.

Capping method: rotary screwing cap

Rotary cap motor: 140W AC motor

Production capacity: 1200-1800 per hour.

Conveyor drive motor: 550W motor inverter speed regulation

The rack is made of 304 stainless steel and plexiglass.

Model three electromagnetic induction aluminum foil sealing machine

Technical parameters:

Suitable diameter of bottle mouth: 50~80 (mm)

Applicable bottle height: 40~200 (mm)

Production capacity: 1800 bottles / hour

Conveyor belt: 1700 mm long, 82 mm wide

Conveyor speed: 0 ~ 13.5m/min

Rated voltage: 220V / 50Hz

Whole machine power: 3000W

Appearance size: 1700 x 410 x 1350 (mm) (long * width * height)

Weight of whole machine: 100Kg

PET box semi-automatic aluminum foil sealing machine

Main technical parameters:

1, scope of application: plastic box aluminum foil hot seal

2, production capacity: 1200-1800 boxes / hour

3, power supply: 0.3Kw 220V 50Hz

4, gas source: 4-8 kgf/cm*cm

Function:

After automatically putting the box, the aluminum foil, the aluminum foil and the heat sealed aluminum foil are automatically delivered.

Then take the box manually.

(can be customized according to customer requirements)

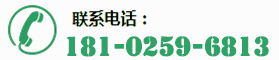

Filling machine

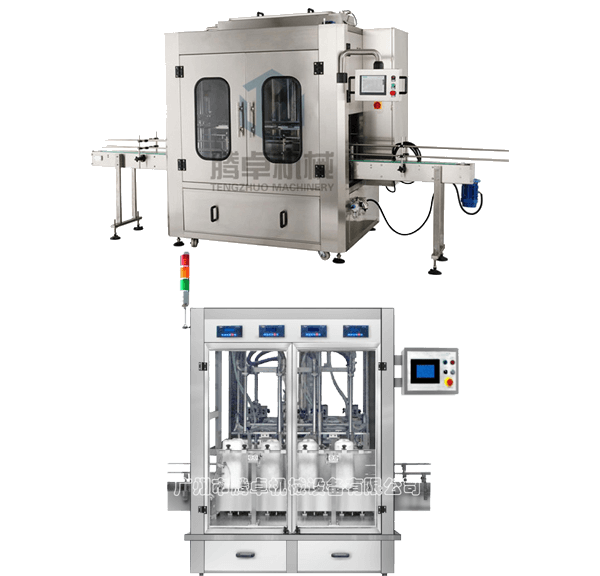

Filling machine Labeling machine

Labeling machine Screw cap machine

Screw cap machine Casing shrink..

Casing shrink.. Bottle washing..

Bottle washing.. Automatic medicin.

Automatic medicin. Automatic filling ..

Automatic filling ..  Automatic filling ..

Automatic filling ..